Our recycling solutions for scrap metal and end-of-life vehicles use industry leading technology to achieve best in class metal recycling rates. We guarantee highly competitive prices and unique social value from your contracts.

RECYCLING AND SUSTAINABILITY

METAL RECYCLING

SOCIAL VALUE

Our unique social programmes are game-changing in offender rehabilitation, and ending food povertyand home Lessness. We create social value from our work that is equal to or greater than 10% of our annuaL salesand then credit this to your contracts

TOTAL WASTE MANAGEMENT

Our services allow you to manage all your waste streams through one provider to achieve 100% recycling rates. We use unique reporting software.to ensure full transparency and allow you to meet all compliance and generate rebates from waste streams.

How mining affect our environment?

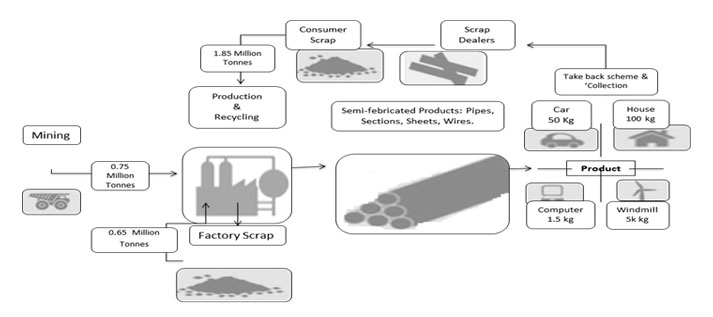

Greenhouse gases have far-ranging environmental and health effects. They cause climate change by trapping heat, and they also contribute to respiratory disease from smog and air pollution. Extreme weather, food supply disruptions, and increased wildfires are other effects of climate changes like huge carbon emission and other toxic gases caused by greenhouse gases and this occurred due to lessen of natural recourses due to mining of ore for the need of raw material for the purpose of new technology, scientific research and human needs. So, to prevent the mining and reserve the natural recourses we have to adopt recycling at large scale.

Why Recycling needed?

Recycling scrap metal preserves natural resources that naturally occur in nature and aren’t renewable. Additionally, producing new metals releases more greenhouse gas emissions than the recycling process does. Similarly, recycling scrap metal uses far less energy and less water than mining for ore.

Recycling of Non-Ferrous Metals

India imported 0.95 million tonnes of Non-Ferrous Metal Scrap in 2013-14 and 1.1 million tonnes in 2014-15. The most commonly used non-ferrous metals are Aluminium, Copper, Lead, Zinc, and precious metals. Millions of tones of Non-ferrous scrap are recovered annually and used by smelters, refiners, ingot makers, foundries, and other manufacturers. Secondary materials are essential to the industry’s survival because even new metals often require the combined use of recycled materials.

Recycling of Aluminium

Recycling aluminium uses 95% less energy than producing aluminium from raw materials. It also saves 97% of green house gas emissions produced in the primary production process. Due to recycling less Greenhouse gasses such as Carbon Dioxide, Carbon Monoxide, Nitrous Oxide and Water Vapour are being produced each year. One-third of Aluminium demand is supplied by secondary production.

Recycling aluminium has five steps:

2. Sorting Scrap

3. Crushing

4. Re-melting

5. Casting

Do You Know?

CO2 emissions are reduced by 92% when Aluminium scrap is used instead of bauxite.

Aluminum has about one-third the density and stiffness of steel. After steel, it is the most frequently used metal in the world and its uses continue to expand. Aluminum is amongst the most environmentally friendly metals on the planet. On a percentage basis, it is the most recycled of any industrial metal.

Recycling of Zinc

Zinc is a lustrous bluish-white metal. It is found in group II-b of the periodic table. It is brittle and crystalline at ordinary temperatures, but it becomes ductile and malleable when heated between 110°C and 150°C. About three-fourths of zinc used is consumed as metal, mainly as a coating to protect iron and steel from corrosion (galvanized metal), as alloying metal to make bronze and brass, as zinc-based die casting alloy, and as rolled zinc.

Zinc is an inherently recyclable non-ferrous metal and can be recycled indefinitely without any loss of physical or chemical properties. At present, approximately 55-60% of zinc comes from primary refining of zinc ores (including 10-15% from recycled sources) and about 40-45% comes directly from recycled zinc (representing 80% of the zinc available for recycling).The recycling level continues to increase as technology improves. The long life of zinc coated steel products in construction makes forecast of their emergence in waste streams difficult to model, hence more work will be required on this.

Of a total worldwide Zinc production of 11 Mt, 10.6 Mt was smelter Zinc in which 4.97 was categorized as either primary or secondary. The remaining 5.63 Mt (53%) was not differentiated. Production from secondary sources is estimated at 7.5% of the differentiated 4.97 Mt. Secondary production uses 76% less energy than primary product.

Recycling of Copper

During the past decade, strong growth in emerging economies, coupled with an increase use of copper for innovative technologies, has led to significantly higher copper demand. The recovery and recycling of copper helps to satisfy this demand and to build a sustainable future for next generation.

Copper is one of the few materials that can be recycled repeatedly without any loss of its performance and 100% recyclable. There is also no difference in the quality of recycled copper (Secondary Production) and mined copper (Primary Production), thus they can be used interchangeably.

Recycling of Copper & its impact on environment:

Recycling saves CO2 and energy. Recycling copper is a highly eco-efficient way of reintroducing a valuable material back into the economy. The recycling of copper requires 80-90% less energy than primary production. Globally, this saves 40 million tonnes of CO2 annually, which is equivalent to taking 16 million passenger cars off the road. In addition to its environmental benefits, the recycling of complex copper scrap (such as electronic waste) drives the recovery of many other metals such as gold, silver, nickel, tin, lead and zinc.

Recycling of Copper & its impact on environment:

It is estimated that nearly 70 percent of worldwide copper produced is used for electrical/conductivity applications and communications due to its highest electrical conductivity than any other metal, apart from silver. This property makes copper the material of choice in power generation and transmission. 45% of produced copper is use for delivering electricity safely and efficiently to homes and businesses. 12.5 % used in electrical equipment like circuitry, wiring and contacts for appliances and consumer electronics. The remaining 12.5 % is used by the transport sector. (The high purity copper wire harness system in a train, car or truck carries the current from the battery throughout the vehicle to equipment such as lights, central locking, on-board computers and satellite navigation systems). 20 % of all the copper produced is used in buildings for plumbing, roofing and cladding. Copper provides light, durable maintenance-free structures that are naturally good looking, long lasting and fully recyclable. The remaining 10 percent is used for coins, sculptures, jewelry, musical instruments, cookware and other consumer goods.

Do You Know?

30% of Copper production comes from copper scrap.

By using Copper scrap, we reduce CO2 emission by

65%.

Do You Know?

Madhya Pradesh is Largest Producer of Copper followed by Rajasthan and Jharkhand respectively a total of about more than153 lakh tonnes.

Copper recycling include material collected from end of life products such as cables and wires, electric hardware as well as the re-melting of factory waste.

Do You Know?

50% of the world’s Lead production originates

from secondary lead. Using secondary Lead

instead of ore reduces CO2 emissions by 99%.

Do You Know?

About 1.44 Mt of Nickel is produced worldwide every year. Of this total production, 0.35 Mt is recycled nickel, made from 4.5 Mt of scrap. The carbon footprint of Nickel using primary production is 90% higher than that of secondary smelting.